Product Characteristics

The oil-cooling series slurry automatic separator is the market demand of our factory combined with non-metallic minerals. It integrates the advantages of large-scale magnetic separation equipments at home and abroad. After the latest research and development of the company’s R&D personnel, it introduced a large output, low energy consumption iron removal equipment. After practical application, it will play an obvious sorting effect on weakly magnetic nonmetal minerals such as mica, iron oxide, and titanium that are difficult to sort, making the quality of the treated minerals greatly improved and the added value of minerals increased,which has been widely praised and supported by customers.

Scope of application

It is suitable for metal ore rough selection and non-metallic mineral purification. Purification of quartz, feldspar, kaolin and other non-metallic minerals. Other industries: wastewater treatment in steel plants and power plants.

- Water and oil dual medium cooling system designed to effectively control temperature rise.

- Intelligent control, there is no need to manual operation.

- More than 30% energy saving, greatly reduce operating cost.

- Strong environmental adaptability, especially suitable for mining environment.

| Model | Rated Voltage | Max Coil Power | Rated Background Magnetic Field | Magnetic cavity diameter | Ore-feeding size | Yield | Pipe size | Machine weight | DimensionLxWxH(mm) |

|---|---|---|---|---|---|---|---|---|---|

| WY750-V | 380 V | 82 KW | 2 T | 750 mm | ≥20 mesh | 15-80 m³/h | 6 in | 16 T | 2958x2294x3091 |

| WY1000-VB | 380 V | 120 KW | 2 T | 1000 mm | ≥20 mesh | 30-130 m³/h | 8 in | 28 T | 3503x2658x3392 |

| WY1000-V | 380 V | 120 KW | 2 T | 1000 mm | ≥20 mesh | 30-130 m³/h | 8 in | 45 T | 3674x2737x3542 |

| WY1200-V | 380 V | 150 KW | 2 T | 1200 mm | ≥20 mesh | 50-150 m³/h | 10 in | 53 T | 3950x2926x3746 |

| WY1500-V | 380 V | 180 KW | 2 T | 1500 mm | ≥20 mesh | 50-180 m³/h | 12 in | 65 T | 4349x3240x3706 |

* Please contact us for more details.

* Yield depends on material concentration and pressure.

* Various conditions or factors may cause deviations, please prevail in kind.

Applicable Industry

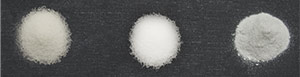

Sample Comparison Before And After Magnetic Separation

India Sodium potassium feldspar

Original Ore : 16

After : 60.1

Vietnam kaolin

Original Ore : 69.5

After : 88.2

Henan Sodium potassium feldspar

Original Ore : 14

After : 67.2

Fujian kaolin

Original Ore : 73.3

After : 91

Shandong Sodium potassium feldspar

Original Ore : 33

After : 74.6

Heyuan kaolin

Original Ore : 70.8

After : 86.3

Hebei Sawdust tailings

Original Ore : 6.2

After : 71.4

Hebei Sawdust tailings

Original Ore After Iron