Product Characteristics

Program Controlled Automatic Water-cooling Electromagnetic Slurry Separator Series is a new model of separator with high efficiency. The machine cools itself by deionized water circulating in the hollow copper pipe through circulating pump. Owing to the special structure, water-cooling Eletromagnetic slurry separator have the following advantages: high intensity magnetic field; the temperature inside of the machine rises slowly, long working period, have a wide range of adaption in the particle of feeding ore and the thickness of slurry; high efficiency in mineral processing; easy to manual and maintain.

Scope of application

Water-cooling electromagnetic slurry program-controlled automatic iron removal machine is suitable for metal ore rough selection and non-metallic mineral purification. Purification of quartz, feldspar, kaolin and other non-metallic minerals. Other industries: wastewater treatment in steel plants and power plants.

- The new efficient cavity structure is optimized, and the effect and efficiency of iron removal are obviously improved.

- Intelligent control, there is no need to manual operation.

- Cooling system of water cooling.

- Simple maintenance and low cost.

| Model | Rated Voltage | Max Coil Power | Rated Background Magnetic Field | Magnetic cavity diameter | Ore-feeding size | Yield | Pipe size | Machine weight | DimensionLxWxH(mm) |

|---|---|---|---|---|---|---|---|---|---|

| WS500-V | 380 V | 75 KW | 1.6 T | 500 mm | ≥20 mesh | 20-50 m³/h | 4 in | 14 T | 2328x1745x2642 |

| WS750-V | 380 V | 103 KW | 1.6 T | 750 mm | ≥20 mesh | 30-80 m³/h | 6 in | 16.6 T | 2659x1978x2518 |

| WS1000-V | 380 V | 150 KW | 1.6 T | 1000 mm | ≥20 mesh | 30-130 m³/h | 8 in | 26 T | 3052x2185x2814 |

* Please contact us for more details.

* Various conditions or factors may cause deviations, please prevail in kind.

Applicable Industry

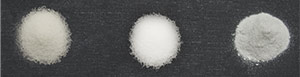

Sample Comparison Before And After Magnetic Separation

India Sodium potassium feldspar

Original Ore : 16

After : 60.1

Vietnam kaolin

Original Ore : 69.5

After : 88.2

Henan Sodium potassium feldspar

Original Ore : 14

After : 67.2

Fujian kaolin

Original Ore : 73.3

After : 91

Shandong Sodium potassium feldspar

Original Ore : 33

After : 74.6

Heyuan kaolin

Original Ore : 70.8

After : 86.3

Hebei Sawdust tailings

Original Ore : 6.2

After : 71.4

Hebei Sawdust tailings

Original Ore After Iron